Who knows. I’m sure somewhere in Manhattan

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Snorkel

- Thread starter jloonz

- Start date

Nope, not yet, it was bought with federal money so they’re not really losing by not using it

Here is good two part Question that comes mind when I saw that construction Crain fire this morning,

1 Would a 230 foot Bronto Skylift have made a difference in attacking that fire this morning?

2 Would the Ferrara 5,250 GPM , Super Pumper 1 had made a difference in fighting the crane fire.? I know that Industrial pumpers are capabable of sending High Power Streams into the air ,

1 Would a 230 foot Bronto Skylift have made a difference in attacking that fire this morning?

2 Would the Ferrara 5,250 GPM , Super Pumper 1 had made a difference in fighting the crane fire.? I know that Industrial pumpers are capabable of sending High Power Streams into the air ,

Bulldog

Bulldog

- Joined

- Apr 16, 2008

- Messages

- 2,305

The Bronto would not have done any good because the fire was over 40 stories up so would still be well short of reaching the crane. I'm not sure about super pumper but I doubt it would have been any good either, it's more designed for volume than it is for pressure. Probably 1 of the 3 stage high-pressure pumpers would have been just as effective but I doubt even a stream from 1 of those would've reached the fire.Here is good two part Question that comes mind when I saw that construction Crain fire this morning,

1 Would a 230 foot Bronto Skylift have made a difference in attacking that fire this morning?

2 Would the Ferrara 5,250 GPM , Super Pumper 1 had made a difference in fighting the crane fire.? I know that Industrial pumpers are capabable of sending High Power Streams into the air ,

- Joined

- Apr 1, 2007

- Messages

- 4,353

One of the high pressure pumpers (E-10) WAS special called.Probably 1 of the 3 stage high-pressure pumpers would have been just as effective but I doubt even a stream from 1 of those would've reached the fire.

- Joined

- Jun 27, 2007

- Messages

- 3,769

Not an expert on water hydraulics but fighting a fire 40+ stories up would be difficult via a high pressure stream. Would the stream stay together to be effective? In addition to friction loss aren't you also fighting gravity? All that water going up would have to come back down with force behind it, how about some collateral damage? Just asking?The Bronto would not have done any good because the fire was over 40 stories up so would still be well short of reaching the crane. I'm not sure about super pumper but I doubt it would have been any good either, it's more designed for volume than it is for pressure. Probably 1 of the 3 stage high-pressure pumpers would have been just as effective but I doubt even a stream from 1 of those would've reached the fire.

- Joined

- Apr 1, 2007

- Messages

- 4,353

I'm no hydraulics expert either, Grump, but it seems to me that any stream of water will disperse as it gets further from its source . . . and in the case of a 40 story tall stream (if it were even possible to do that), it would be very diffuse by the time it got to its apex, and even more so by the time it came back down. And probably no more dangerous than a heavy rain. Anybody out there knowledgeable enough to confirm or deny?Not an expert on water hydraulics but fighting a fire 40+ stories up would be difficult via a high pressure stream. Would the stream stay together to be effective? In addition to friction loss aren't you also fighting gravity? All that water going up would have to come back down with force behind it, how about some collateral damage? Just asking?

Bulldog

Bulldog

- Joined

- Apr 16, 2008

- Messages

- 2,305

Yes keep the stream together would certainly be the most difficult part. The streams from the adjacent buildings were holding together pretty good but they were not fighting gravity.I'm no hydraulics expert either, Grump, but it seems to me that any stream of water will disperse as it gets further from its source . . . and in the case of a 40 story tall stream (if it were even possible to do that), it would be very diffuse by the time it got to its apex, and even more so by the time it came back down. And probably no more dangerous than a heavy rain. Anybody out there knowledgeable enough to confirm or deny?

- Joined

- Sep 25, 2013

- Messages

- 996

Exactly. The reach of a stream operated from 600 feet up is no different than a stream operated at ground level. As it breaks up into droplets, it becomes just like rain. Getting pressure up to that height is the challenge. Building fire pumps are critical.I'm no hydraulics expert either, Grump, but it seems to me that any stream of water will disperse as it gets further from its source . . . and in the case of a 40 story tall stream (if it were even possible to do that), it would be very diffuse by the time it got to its apex, and even more so by the time it came back down. And probably no more dangerous than a heavy rain. Anybody out there knowledgeable enough to confirm or deny?

I'm not an expert but I did teach pump and hydraulics for my fd for new engineers and refreshers.

When we talk hirise situations or in this case a crane, there's several things that have a major impact on water supply.

First, is the material the supply is made out of. Most sandpipe systems are rated to 150 psi with a max of 200 psi. There usually tested higher but considering lack of maint, etc. I'd be very cautious approaching 200. Size is also another factor. The average hose line, for attack has a service pressure I think of about 300 psi and a test psi of 600. Supply line is much lower.

Second is head pressure. Which is basically the weight of the water and the force needed to move it 1 floor. That's roughly 5 psi per floor or 10 feet. It's probably a little higher when you factor in the floor/ceiling depth, and any drop or dead space for utilities.

Third is what is supplying it. Most normal supply lines for a sandpiper system can only move up to a certain amount of water before maxing out. For example 5 inch supply lines will max out at roughly 1250 gpms, before capacity starts to drop as pressure increases.

Third is friction loss. Every hose, pipe nozzle, appliance has friction loss. And no 2 hoses are the same. When I was specing hoses for our new engines and replacement hoses, I was surprised that FDNYs hose specs are pretty high in comparison to some of the new stuff out there today.

Fourth is gpm. How much water do you want or need?

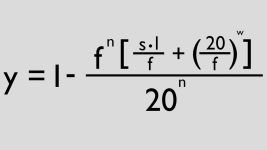

So, looking at this scenario.

We have a crane that's roughly 450 feet tall.

Just to overcome the head pressure, you would need 225 psi.

Now add in roughly 80 psi for the average master stream smooth bore, plus another 20 psi for the for the swivel piping it's attached to, and we're up to 325. Add in friction loss for what supply the master stream ( engine deck gun or is it a tower. You would have friction loss between the engine supplying it, and the tower, plus another 20 psi for the towers intake) and we go even higher.

On average the breakover point or the point where the stream loses its cohesion or shape varies but in perfect conditions, is roughly 75 to 100 feet.

The next problem is the towers or at least the average towers are not rated for those pressures. Industrial towers maybe, but I haven't really looked at the specs. Seen 1 up close. I don't think the average monitor on the tops of the engines would take that pressure either before something comes apart or leaks. Maybe the high pressure units or the satellites.

And you would still come up 2 to 300 feet short.

The way they get around it in building is installing fire pumps every so many stories and or dividing the building into zones. If you look at some taller buildings, the fdcs are marked flors 1-10 11- 20 etc. for that reason.

When we talk hirise situations or in this case a crane, there's several things that have a major impact on water supply.

First, is the material the supply is made out of. Most sandpipe systems are rated to 150 psi with a max of 200 psi. There usually tested higher but considering lack of maint, etc. I'd be very cautious approaching 200. Size is also another factor. The average hose line, for attack has a service pressure I think of about 300 psi and a test psi of 600. Supply line is much lower.

Second is head pressure. Which is basically the weight of the water and the force needed to move it 1 floor. That's roughly 5 psi per floor or 10 feet. It's probably a little higher when you factor in the floor/ceiling depth, and any drop or dead space for utilities.

Third is what is supplying it. Most normal supply lines for a sandpiper system can only move up to a certain amount of water before maxing out. For example 5 inch supply lines will max out at roughly 1250 gpms, before capacity starts to drop as pressure increases.

Third is friction loss. Every hose, pipe nozzle, appliance has friction loss. And no 2 hoses are the same. When I was specing hoses for our new engines and replacement hoses, I was surprised that FDNYs hose specs are pretty high in comparison to some of the new stuff out there today.

Fourth is gpm. How much water do you want or need?

So, looking at this scenario.

We have a crane that's roughly 450 feet tall.

Just to overcome the head pressure, you would need 225 psi.

Now add in roughly 80 psi for the average master stream smooth bore, plus another 20 psi for the for the swivel piping it's attached to, and we're up to 325. Add in friction loss for what supply the master stream ( engine deck gun or is it a tower. You would have friction loss between the engine supplying it, and the tower, plus another 20 psi for the towers intake) and we go even higher.

On average the breakover point or the point where the stream loses its cohesion or shape varies but in perfect conditions, is roughly 75 to 100 feet.

The next problem is the towers or at least the average towers are not rated for those pressures. Industrial towers maybe, but I haven't really looked at the specs. Seen 1 up close. I don't think the average monitor on the tops of the engines would take that pressure either before something comes apart or leaks. Maybe the high pressure units or the satellites.

And you would still come up 2 to 300 feet short.

The way they get around it in building is installing fire pumps every so many stories and or dividing the building into zones. If you look at some taller buildings, the fdcs are marked flors 1-10 11- 20 etc. for that reason.

Last edited:

Compared to the average 95 tower, there not that much heavier. With the Mack engine foward cab, there 85,000 compared to the roughly 77,000 of a Seagrave 95.im curious where they would have housed it as bronto's are really heavy

There's a lot of other issues that a Bronto has, that the average platform doesn't. The main one is the support for those trucks is overseas and everyone I know that has one, has issues with parts availability and support. I was talking with some guys from Orange County here in Fl and they are replacing both of their brontos with platforms due to the extended downtimes.

Add in wider jack setup, less and smaller compartments and you can see how they aren't as appealing as they once were.

- Joined

- Jun 27, 2007

- Messages

- 3,769

Thanx for explaining a complex scenario into everyday layman terms and conditions/reactions.I'm not an expert but I did teach pump and hydraulics for my fd for new engineers and refreshers.

When we talk hirise situations or in this case a crane, there's several things that have a major impact on water supply.

First, is the material the supply is made out of. Most sandpipe systems are rated to 150 psi with a max of 200 psi. There usually tested higher but considering lack of maint, etc. I'd be very cautious approaching 200. Size is also another factor. The average hose line, for attack has a service pressure I think of about 300 psi and a test psi of 600. Supply line is much lower.

Second is head pressure. Which is basically the weight of the water and the force needed to move it 1 floor. That's roughly 5 psi per floor or 10 feet. It's probably a little higher when you factor in the floor/ceiling depth, and any drop or dead space for utilities.

Third is what is supplying it. Most normal supply lines for a sandpiper system can only move up to a certain amount of water before maxing out. For example 5 inch supply lines will max out at roughly 1250 gpms, before capacity starts to drop as pressure increases.

Third is friction loss. Every hose, pipe nozzle, appliance has friction loss. And no 2 hoses are the same. When I was specing hoses for our new engines and replacement hoses, I was surprised that FDNYs hose specs are pretty high in comparison to some of the new stuff out there today.

Fourth is gpm. How much water do you want or need?

So, looking at this scenario.

We have a crane that's roughly 450 feet tall.

Just to overcome the head pressure, you would need 225 psi.

Now add in roughly 80 psi for the average master stream smooth bore, plus another 20 psi for the for the swivel piping it's attached to, and we're up to 325. Add in friction loss for what supply the master stream ( engine deck gun or is it a tower. You would have friction loss between the engine supplying it, and the tower, plus another 20 psi for the towers intake) and we go even higher.

On average the breakover point or the point where the stream loses its cohesion or shape varies but in perfect conditions, is roughly 75 to 100 feet.

The next problem is the towers or at least the average towers are not rated for those pressures. Industrial towers maybe, but I haven't really looked at the specs. Seen 1 up close. I don't think the average monitor on the tops of the engines would take that pressure either before something comes apart or leaks. Maybe the high pressure units or the satellites.

And you would still come up 2 to 300 feet short.

The way they get around it in building is installing fire pumps every so many stories and or dividing the building into zones. If you look at some taller buildings, the fdcs are marked flors 1-10 11- 20 etc. for that reason.

If the FDNY does want to get something tall, I would suggest looking into what the use case would be. What do you want to use it for/what capability is prioritized?

If you prioritize reaching in over large footprint fire buildings for operating a master stresm and/or using the basket as a stable platform for venting when a roof may have compromised stability, and/or removing people from high altitude on stretchers or in wheelchairs, Bronto is probably the best bet.

If however you want to evacuate a larger number of people from up high that’s going to take a long if you need to bring them down in the basket, then up again etc.

I would suggest that if that is the priority, it’s a better bet to consider going the London Fire Brigade route and get a tall Magirus ladder with a basket elevator. That offers a much higher flow of people. Currently they offer a 223 feet version.

Here’s some photos and info from the manufacturer.

If you prioritize reaching in over large footprint fire buildings for operating a master stresm and/or using the basket as a stable platform for venting when a roof may have compromised stability, and/or removing people from high altitude on stretchers or in wheelchairs, Bronto is probably the best bet.

If however you want to evacuate a larger number of people from up high that’s going to take a long if you need to bring them down in the basket, then up again etc.

I would suggest that if that is the priority, it’s a better bet to consider going the London Fire Brigade route and get a tall Magirus ladder with a basket elevator. That offers a much higher flow of people. Currently they offer a 223 feet version.

Here’s some photos and info from the manufacturer.

Magirus M68L - The world's highest turntable ladder

A completely new dimension: The Magirus M68L turntable ladder is currrently the highest turntable ladder in the world. The vehicle officially presented at the 2015 Interschutz exhibition has a working height of 68 meters - and sets standards beyond height. According to EN 1846 and DIN EN 14043, the vehicle perfectly fulfills all requirements of assigned duties like rescuing people from great height, firefighting or providing technical assistance.

Concept:

Technical data

Working height: 68 m Rescue cage: RC300 for 3 persons / 300 kg Chassis type: Appropriate three- or four-axle chassis, 34 t class, e.g. Iveco Trakker or Scania P Ladder set: 7 sections Characteristics:

Innovative technologies are our standard

The main control stand: Where ergonomics meets design

A wide access and the ergonomic protection bar offer more safety when entering the main control stand. The heated seating area is spacious and allows crews to sit comfortably in firefighting gear. The angle of seat inclination is automatically set depending on the ladder angle while individual adjustments can be made at any time. The colour display swivels into its working position at the touch of a button and can be easily operated with one hand.

Get to know more about our TTL design.

For demanding tasks: The RE300 rescue lift

The rescue lift for Magirus turntable ladders was redeveloped for even better performance. It has a load capacity of 300 kg or 3 persons plus additional load. The rescue lift goes from the ladder top completely to the floor of the vehicle parking area. This guarantees simpler and faster exits directly on safe ground. The lift ride is automatically controlled while the speed can be set individually. Due to the simplified crossover function, the lift provides invaluable help when crews must be transported from the ground to the top and thus to the deployment site.

Further included technologies

XLL VARIO jacking system

The XLL VARIO jacking system was custom-built for Magirus turntable ladders with working heights of more than 55 m. It ensures maximum reliability and stability - even on inclined or slippery surfaces. The smooth outreach control allows flexible adaption of outreach. It can be operated fast and easy while providing an extremely fast set-up.RC300 rescue cage

The RC 300 is a spacious cage that enables many possible uses while simultaneously allowing the most extreme turntable ladder outreach.

- Payload 300 kg

- Two multifunctional columns positioned at the sides

- Control stand in the cage centre

- Four sockets (1 x 400 V, 3 x 230 V)

- LED floodlights integrated in the cage front

- Removable water monitor; waterway runs outside of the cage; max. 2,500 l/min

- Practical corner entrances

- Fold-away doors on the sides and protection bars enable unhindered access – important for those wearing breathing masks

Options:

To ensure that firefighters are well equipped for any job, we offer a wide range of special equipment and functional accessories to make Magirus turntable ladders efficient rescue devices. These are some possible options for the M68L:

For the most diverse missions.

- “Magirus Edge Light“ safety lighting built into the bottom profile

- Telescopic water pipe at the ladder set

- Manually or electrically controlled water monitor, adjustable

- Power supply to cage and various types of illumination

- Thermal imaging / real imaging camera at cage

- Positive pressure ventilator storage at cage

- 360° swivel device for stretcher: 200 kg

- Self-protection nozzles at cage floor

- Radio remote control for elevator

- Remote diagnostic system

- Fire-fighting centrifugal pump & foam proportioning systems

- Variable custom design and painting options

Lol. When I first started learning to pump, the running joke was increase the pressure until the nozzlemans feet came off the ground, then back down about 10 psi.

While this sounds good in theory, because this is a Eurpopean unit, it probably doesn't meet the US NFPA requirements. I think it was Rosenbauer that had a hard time getting there units certed for use in the US. NFPA basically is a National Standard that governs anything and everything regarding fire equipment. It's full name is National Fire Protection Agency. There standards for anything you can think of. Last time I looked they were over 2000 standards. The hose testing numbers I mentioned above, and I was off are set by NFPA. The burst pressure is not less then 1600 psi in some cases, and test pressure is 500 psi. For aerial devices, NFPA states if I remember correctly was the steps or rungs couldn't be more then a certain distance apart, a certain thickness, and a certain shape and diameter. And that's what was one of the thing tripping up Rosenbauer if I recall correctly.If the FDNY does want to get something tall, I would suggest looking into what the use case would be. What do you want to use it for/what capability is prioritized?

If you prioritize reaching in over large footprint fire buildings for operating a master stresm and/or using the basket as a stable platform for venting when a roof may have compromised stability, and/or removing people from high altitude on stretchers or in wheelchairs, Bronto is probably the best bet.

If however you want to evacuate a larger number of people from up high that’s going to take a long if you need to bring them down in the basket, then up again etc.

I would suggest that if that is the priority, it’s a better bet to consider going the London Fire Brigade route and get a tall Magirus ladder with a basket elevator. That offers a much higher flow of people. Currently they offer a 223 feet version.

Here’s some photos and info from the manufacturer.

View attachment 38440View attachment 38441View attachment 38442View attachment 38443

Even Bronto, which is made by EOne and the Pierce Trex are only compliant to a certain height. I think after 118 or 120, they are no longer compliant. Might be 130. Theres very little info out there.

Yes, and that’s probably an issue. Although if I’m remembering correctly the FDNY doesn’t actually follow the NFPA regs religiously? Like isn’t the tower ladder baskets non-compliant for instance, because the FDNY disagrees with what’s the best practice/layout?While this sounds good in theory, because this is a Eurpopean unit, it probably doesn't meet the US NFPA requirements. I think it was Rosenbauer that had a hard time getting there units certed for use in the US. NFPA basically is a National Standard that governs anything and everything regarding fire equipment. It's full name is National Fire Protection Agency. There standards for anything you can think of. Last time I looked they were over 2000 standards. The hose testing numbers I mentioned above, and I was off are set by NFPA. The burst pressure is not less then 1600 psi in some cases, and test pressure is 500 psi. For aerial devices, NFPA states if I remember correctly was the steps or rungs couldn't be more then a certain distance apart, a certain thickness, and a certain shape and diameter. And that's what was one of the thing tripping up Rosenbauer if I recall correctly.

Even Bronto, which is made by EOne and the Pierce Trex are only compliant to a certain height. I think after 118 or 120, they are no longer compliant. Might be 130. Theres very little info out there.

Most departments don't for 1 reason or another. It's probably next to impossible to be completely compliant on everything. You go for the big things like age or numbers of equipment.Yes, and that’s probably an issue. Although if I’m remembering correctly the FDNY doesn’t actually follow the NFPA regs religiously? Like isn’t the tower ladder baskets non-compliant for instance, because the FDNY disagrees with what’s the best practice/layout?

I don't know too much about the FDNY baskets other then they come from Seagrave/Aerialscope. I know FDNY writes their specs and I presume they are NFPA certed. Whoever wins the bid would make sure of that. They'd tell them before hand hey we can't do this because of NFPA, we can do this instead. Or what do you want to do?

I doubt that Seagrave or any manufacturer or dealer would allow any department to make a non compliant change to any of their units before it left their possession. Simply because the liability would come back on them if something were to happen. Now any department can go above what is required. You just can't go below the minimum that NFPA says. The other problem is warranty. You do something that causes issues, and you may be on your own.

Layouts are a different story. You can you can lay out your unit however you want. As long as your within the limits of that unit and NFPA. I know of at least 1 dept that ran a 75 foot quint that had basic pump panel controls on the turntable pedestal. Came from Eone that way.

- Joined

- Apr 1, 2007

- Messages

- 4,353

Back in the late '60s or early '70s, Calavar promoted their Firebird 150 (see image) which had a 150 foot reach, and FDNY tried two 144 foot Mack/Magirus "High Ladders" (https://www.nycfire.net/forums/threads/high-ladders.6008/). Neither were successful. If I'm not mistaken, these were the tallest aerial appliances ever in service in the US.

- Joined

- Dec 14, 2014

- Messages

- 224

bet Pierce could build something custom like the European unitWhile this sounds good in theory, because this is a Eurpopean unit, it probably doesn't meet the US NFPA requirements. I think it was Rosenbauer that had a hard time getting there units certed for use in the US. NFPA basically is a National Standard that governs anything and everything regarding fire equipment. It's full name is National Fire Protection Agency. There standards for anything you can think of. Last time I looked they were over 2000 standards. The hose testing numbers I mentioned above, and I was off are set by NFPA. The burst pressure is not less then 1600 psi in some cases, and test pressure is 500 psi. For aerial devices, NFPA states if I remember correctly was the steps or rungs couldn't be more then a certain distance apart, a certain thickness, and a certain shape and diameter. And that's what was one of the thing tripping up Rosenbauer if I recall correctly.

Even Bronto, which is made by EOne and the Pierce Trex are only compliant to a certain height. I think after 118 or 120, they are no longer compliant. Might be 130. Theres very little info out there.