You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FDNY and NYC Firehouses and Fire Companies - 2nd Section

- Thread starter mack

- Start date

ENGINE 207/LADDER 110/SATELLITE 6/BATTALION 31/DIVISION 11 (CONTINUED)

LADDER 110

ENGINE 207/LADDER 110

https://www.picuki.com/media/2310010883344395720

LADDER 110

ENGINE 207/LADDER 110

https://www.picuki.com/media/2310010883344395720

Last edited:

ENGINE 207/LADDER 110/SATELLITE 6/BATTALION 31/DIVISION 11 (CONTINUED)

SUPER PUMPER SYSTEM 172 TILLARY STREET 1972-1975

Robert Avsec

Product News

The greatest fire pumper the world has known

This semi-pulled pumper system designed by a naval engineer redefined "big water"

May 8, 2020

From 1965 through 1982, the T-Rex of fire pumpers roamed the streets of New York City, bringing with it massive firefighting power heretofore unseen on land.

How massive, you ask?

The central pumping unit alone could draw water from eight hydrants at once, drop lines into bodies of water, supply a mind-boggling number of lines with water simultaneously, and flow over 10,000 gallons per minute at low pressures if the situation called for it. When the pressure was ramped up to 350 psi, it could move 8,800 gpm.

By the time of its retirement in April 1982, FDNY's super pumper had responded to more than 2,200 calls. During its 17-year run, the super pumper and its tender and satellite tenders had responded to the biggest fires across the city's five boroughs; once it even took over the task of a failed pumping station in the city's municipal water supply.

William Francis Gibbs, an internationally renowned naval architect, first came up with the idea for a land fireboat (a super pumper) around 1910. But his ideas did not receive serious consideration. Gibbs would eventually design 74% of the U.S. Navy's fleet used during World War II, along with the passenger liner S.S. United States.

Technology, or rather the lack of it, was the insurmountable barrier to Gibbs' idea taking off. Diesel engines that could fulfill this type of pumping requirement and be light enough to mount on a truck did not yet exist, nor did hose that could cope with the water pressures in Gibbs' design.

FIRE RAVAGES STATEN ISLAND

Toward the end of World War II, the British Navy provided the solution to the former with the development of a functional lightweight diesel engine by the Napier Motor Company, while the U.S. Navy would develop the necessary high-pressure hoses to solve that problem.

Beginning in 1962, Gibbs invited Mack Trucks to take part in designing super pumper and its companion tender. DeLaval Turbine was commissioned to design a multi-stage centrifugal pump with a Naper-Deltic T18-37C diesel to power the pumps.

But what really helped birth the super pumper was Black Saturday. On April 20, 1963, FDNY experienced the busiest day in its history. Several dry spells combined with prolonged water shortages led to one of the biggest fires on Staten Island.

At that time, Staten Island was mainly thick brush, oak and pine trees with small clusters of homes. Beginning with a series of small brush fires, all of Staten Island's fire companies were soon in action. Additional fire companies were dispatched from Brooklyn and Manhattan because of the lack of available water (due to the drought) and poor water mains.

The mutual-aid companies' response was hampered because man and machine had to be shipped by ferry to Staten Island. More than 80 fire companies with more than 1,300 firefighters engaged the fires that resulted in property losses in excess of $2 million — that's $16.8 million in 2020 dollars. Firefighters in the rest of NYC were kept busy in that 24-hour period with over 2,000 alarms.

BIRTH OF A BEAST

Gibbs watched the events of that day and knew that the time had come for his land fireboat. Such a beast could have pumped water from the Tottenville waterfront and provided an unlimited supply of water to the working companies on Staten Island.

He approached FDNY officials who were enthusiastic about the idea of a large, high-pressure pumping appliance.

But there was one problem: The department's funding for the next fiscal year had been budgeted. Gibbs was a persistent man, though, so this was just another small setback.

Gibbs testified before several hearings to justify the expense and eventually the New York officials approved the funding. The contract that called for Mack Trucks to build the super pumper and its tender had a price tag of $875,000.

Said then-Fire Commissioner Edward Thompson, "This will be the most powerful firefighting equipment the world has ever known."

THE SUPER PUMPER

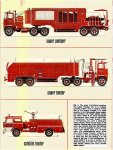

The super pumper was part of a five-truck system that included the super pumper, the tender, and three satellite tenders.

The super pumper itself was a tractor-drawn unit that resembled today's recreational motor homes with many slide-outs and pieces of equipment that were engaged once the unit was in position. The routine setup time to get it operational was about an hour.

The super pumper had a commercial Mack truck for its tractor. Its engine was a four-stroke Mack END864 V8 diesel delivering 255 hp; an Allison CLT4460 six-speed semi-automatic transmission was equipped for a power take-off (PTO) unit to drive the priming pump and the pump engine's starting air compressor. Additional PTO units powered the air brake compressor including the power steering pump. The semi-trailer was mounted to the fifth wheel of the tractor.

Mounted at the rear of the tractor-trailer was a DeLaval six-stage pump that had a piston-type valve to allow for operation in either pressure or volume positions.

To supply water to the pump there were four unchecked inlets to the rear. Two of these were 4½ inch while the other two were 12-inch with 4½-inch inlets set into their caps; there were also two 4½-inch checked inlets on each side of the apparatus at the rear. There were eight 4½-inch discharge outlets with four located on each side.

A mechanical crane was located at the rear of the trailer to assist in positioning and supporting the sections of rigid 12-inch suction hose use for drafting.

Directly coupled to the pump was the Napier-Deltic engine, an 18-cylinder turbo-blown compression ignition, water-cooled, opposed-piston type operating on a two-stroke cycle. The fuel for the pump came from twin 200-gallon tanks, which could feed the diesel independently or simultaneously. The pump engine was started by 450 psi of air pressure from air tanks located on the tractor.

THE TENDER AND SATELLITES

The tender used the same basic Mack cab-over tractor as that of the super pumper with modifications that added an operating platform to support the high-pressure monitor. It was equipped with a Stang Intelligiant monitor that had an 8-inch barrel capable of flowing 10,000 gpm. The monitor could propel its stream 600 feet.

The monitor was supplied via the four 4½-inch checked inlets with two located on each side of the tractor. There were also hydraulically operated outriggers on each side below the operating platform to stabilize the rig and counteract the nozzle reaction from the water cannon up top. The bulk of the trailer consisted of a divided hose bed with each compartment capable of carrying 1,000 feet of 4½-inch hose.

The tender was designed so that the tractor could easily uncouple from the trailer. This allowed for the tractor, carrying the large monitor, to maneuver into tighter spots than would be possible as a tractor-trailer combination.

The three satellite tenders were built on the Mack C model chassis. Each was capable of carrying 2,000 feet of 4½-inch hose and had a Stang Intelligiant monitor with a manually controlled 6-inch barrel that could each deliver 4,000 gpm.

All three satellite tenders had portable manifolds equipped with 4½-inch inlets and either six 2½-inch gated outlets or two 3-inch and four 2½-inch gated outlets. Those portable manifolds — each weighing a little over 200 pounds — were used at operations requiring many hand lines.

The super pumper could supply the manifolds from a remote location with the manifold positioned in front of the fire scene.

Just how awesome was the super pumper system? In 1967, it responded to a fire at a postal annex and managed to supply water to the massive gun on the tender, all three of its three satellite tenders, two tower ladder trucks, and a portable manifold with multiple hand lines all by itself.

Any way you slice it, that's impressive.

www.firerescue1.com

www.firerescue1.com

SUPER PUMPER SYSTEM 172 TILLARY STREET 1972-1975

Robert Avsec

Product News

The greatest fire pumper the world has known

This semi-pulled pumper system designed by a naval engineer redefined "big water"

May 8, 2020

From 1965 through 1982, the T-Rex of fire pumpers roamed the streets of New York City, bringing with it massive firefighting power heretofore unseen on land.

How massive, you ask?

The central pumping unit alone could draw water from eight hydrants at once, drop lines into bodies of water, supply a mind-boggling number of lines with water simultaneously, and flow over 10,000 gallons per minute at low pressures if the situation called for it. When the pressure was ramped up to 350 psi, it could move 8,800 gpm.

By the time of its retirement in April 1982, FDNY's super pumper had responded to more than 2,200 calls. During its 17-year run, the super pumper and its tender and satellite tenders had responded to the biggest fires across the city's five boroughs; once it even took over the task of a failed pumping station in the city's municipal water supply.

William Francis Gibbs, an internationally renowned naval architect, first came up with the idea for a land fireboat (a super pumper) around 1910. But his ideas did not receive serious consideration. Gibbs would eventually design 74% of the U.S. Navy's fleet used during World War II, along with the passenger liner S.S. United States.

Technology, or rather the lack of it, was the insurmountable barrier to Gibbs' idea taking off. Diesel engines that could fulfill this type of pumping requirement and be light enough to mount on a truck did not yet exist, nor did hose that could cope with the water pressures in Gibbs' design.

FIRE RAVAGES STATEN ISLAND

Toward the end of World War II, the British Navy provided the solution to the former with the development of a functional lightweight diesel engine by the Napier Motor Company, while the U.S. Navy would develop the necessary high-pressure hoses to solve that problem.

Beginning in 1962, Gibbs invited Mack Trucks to take part in designing super pumper and its companion tender. DeLaval Turbine was commissioned to design a multi-stage centrifugal pump with a Naper-Deltic T18-37C diesel to power the pumps.

But what really helped birth the super pumper was Black Saturday. On April 20, 1963, FDNY experienced the busiest day in its history. Several dry spells combined with prolonged water shortages led to one of the biggest fires on Staten Island.

At that time, Staten Island was mainly thick brush, oak and pine trees with small clusters of homes. Beginning with a series of small brush fires, all of Staten Island's fire companies were soon in action. Additional fire companies were dispatched from Brooklyn and Manhattan because of the lack of available water (due to the drought) and poor water mains.

The mutual-aid companies' response was hampered because man and machine had to be shipped by ferry to Staten Island. More than 80 fire companies with more than 1,300 firefighters engaged the fires that resulted in property losses in excess of $2 million — that's $16.8 million in 2020 dollars. Firefighters in the rest of NYC were kept busy in that 24-hour period with over 2,000 alarms.

BIRTH OF A BEAST

Gibbs watched the events of that day and knew that the time had come for his land fireboat. Such a beast could have pumped water from the Tottenville waterfront and provided an unlimited supply of water to the working companies on Staten Island.

He approached FDNY officials who were enthusiastic about the idea of a large, high-pressure pumping appliance.

But there was one problem: The department's funding for the next fiscal year had been budgeted. Gibbs was a persistent man, though, so this was just another small setback.

Gibbs testified before several hearings to justify the expense and eventually the New York officials approved the funding. The contract that called for Mack Trucks to build the super pumper and its tender had a price tag of $875,000.

Said then-Fire Commissioner Edward Thompson, "This will be the most powerful firefighting equipment the world has ever known."

THE SUPER PUMPER

The super pumper was part of a five-truck system that included the super pumper, the tender, and three satellite tenders.

The super pumper itself was a tractor-drawn unit that resembled today's recreational motor homes with many slide-outs and pieces of equipment that were engaged once the unit was in position. The routine setup time to get it operational was about an hour.

The super pumper had a commercial Mack truck for its tractor. Its engine was a four-stroke Mack END864 V8 diesel delivering 255 hp; an Allison CLT4460 six-speed semi-automatic transmission was equipped for a power take-off (PTO) unit to drive the priming pump and the pump engine's starting air compressor. Additional PTO units powered the air brake compressor including the power steering pump. The semi-trailer was mounted to the fifth wheel of the tractor.

Mounted at the rear of the tractor-trailer was a DeLaval six-stage pump that had a piston-type valve to allow for operation in either pressure or volume positions.

To supply water to the pump there were four unchecked inlets to the rear. Two of these were 4½ inch while the other two were 12-inch with 4½-inch inlets set into their caps; there were also two 4½-inch checked inlets on each side of the apparatus at the rear. There were eight 4½-inch discharge outlets with four located on each side.

A mechanical crane was located at the rear of the trailer to assist in positioning and supporting the sections of rigid 12-inch suction hose use for drafting.

Directly coupled to the pump was the Napier-Deltic engine, an 18-cylinder turbo-blown compression ignition, water-cooled, opposed-piston type operating on a two-stroke cycle. The fuel for the pump came from twin 200-gallon tanks, which could feed the diesel independently or simultaneously. The pump engine was started by 450 psi of air pressure from air tanks located on the tractor.

THE TENDER AND SATELLITES

The tender used the same basic Mack cab-over tractor as that of the super pumper with modifications that added an operating platform to support the high-pressure monitor. It was equipped with a Stang Intelligiant monitor that had an 8-inch barrel capable of flowing 10,000 gpm. The monitor could propel its stream 600 feet.

The monitor was supplied via the four 4½-inch checked inlets with two located on each side of the tractor. There were also hydraulically operated outriggers on each side below the operating platform to stabilize the rig and counteract the nozzle reaction from the water cannon up top. The bulk of the trailer consisted of a divided hose bed with each compartment capable of carrying 1,000 feet of 4½-inch hose.

The tender was designed so that the tractor could easily uncouple from the trailer. This allowed for the tractor, carrying the large monitor, to maneuver into tighter spots than would be possible as a tractor-trailer combination.

The three satellite tenders were built on the Mack C model chassis. Each was capable of carrying 2,000 feet of 4½-inch hose and had a Stang Intelligiant monitor with a manually controlled 6-inch barrel that could each deliver 4,000 gpm.

All three satellite tenders had portable manifolds equipped with 4½-inch inlets and either six 2½-inch gated outlets or two 3-inch and four 2½-inch gated outlets. Those portable manifolds — each weighing a little over 200 pounds — were used at operations requiring many hand lines.

The super pumper could supply the manifolds from a remote location with the manifold positioned in front of the fire scene.

Just how awesome was the super pumper system? In 1967, it responded to a fire at a postal annex and managed to supply water to the massive gun on the tender, all three of its three satellite tenders, two tower ladder trucks, and a portable manifold with multiple hand lines all by itself.

Any way you slice it, that's impressive.

The greatest fire pumper the world has known

This semi-pulled pumper system designed by a naval engineer redefined "big water"

Attachments

Last edited:

ENGINE 207/LADDER 110/SATELLITE 6/BATTALION 31/DIVISION 11 (CONTINUED)

ENGINE 207 MEDAL

JAMES W. TRIHY FF. ENG. 207 FEB. 1, 1901 1903 BROOKLYN CITIZENS

FF Trihy was awarded the 1903 Brooklyn Citizens Medal for heroism rescuing 3 women at a fire on February 12, 1901 at 158 Myrtle Avenue.

MEDAL DAY 1903

FF TRIHY DRIVER - SEPTEMBER 1903

LT TRIHY DEATH

ENGINE 207 MEDAL

JAMES W. TRIHY FF. ENG. 207 FEB. 1, 1901 1903 BROOKLYN CITIZENS

FF Trihy was awarded the 1903 Brooklyn Citizens Medal for heroism rescuing 3 women at a fire on February 12, 1901 at 158 Myrtle Avenue.

MEDAL DAY 1903

FF TRIHY DRIVER - SEPTEMBER 1903

LT TRIHY DEATH

Last edited:

ENGINE 207/LADDER 110/SATELLITE 6/BATTALION 31/DIVISION 11 (CONTINUED)

LADDER 110 MEDAL

CARL A. MONTELIN FF. LAD. 110 FEB. 27, 1908 1909 HURLEY

FF Montelin was awarded the Hurley Medal in 1909 for the heroic rescue of three people trapped at a fire on February 27, 1908 at 833 Fulton Street.

MEDAL DAY 2009

FIRE BUILDING 833 FULTON STREET

FF MONTELIN PERSONAL ISSUES IN NEWSPAPER 1910

FF MONTELIN PREVENTS ARSON ATTEMPT 1910

LADDER 110 MEDAL

CARL A. MONTELIN FF. LAD. 110 FEB. 27, 1908 1909 HURLEY

FF Montelin was awarded the Hurley Medal in 1909 for the heroic rescue of three people trapped at a fire on February 27, 1908 at 833 Fulton Street.

MEDAL DAY 2009

FIRE BUILDING 833 FULTON STREET

FF MONTELIN PERSONAL ISSUES IN NEWSPAPER 1910

FF MONTELIN PREVENTS ARSON ATTEMPT 1910

There are rumors that the 207/110 84 Pct site is owner by a developer and needs to be vacated in the near future. Anyone have the real story?

Real estate web site lists property owner as "NYPD".

"The property owner's name is Nyc Police Department. The property was built in 1970. The property is 50 years old, which is 38 years younger than the average age of a building in Brooklyn of 88 years. Our analysis shows this property is worth $6,529,050. The living area is 50,000 sqft. The size of the land lot is 38,250 sqft. The building is three stories high. The owners, contractors or their representatives filed five permit applications to perform work at this address. Here are some excerpts from the permit #2836710. On March 09, 2015, the last permit for work at this address was issued. This is a apartment property. The house has a studio bedroom. The property has one full bath. The house has three levels. The house's living area is 50,000 sqft. This address is often written as 172 Tillary Str, NY 11201-2003. The ZIP code for this address is 11201 and the postal code suffix is 2003. The address has the following coordinates: 40.6954934,-73.9828457. Rent value for a two bedroom unit in the zip code 11201 is estimated at $2,930 a month. The main issue in the Downtown Brooklyn neighborhood is illegal parking (99 reports)"

Also - 4 work permits list client for property at 172 Tillary Street as "FDNY"

Could not find anything listing a private owner.

Last edited:

ENGINE 207/LADDER 110/SATELLITE 6/BATTALION 31/DIVISION 11 (CONTINUED)

LADDER 110 MEDALS

JAMES J. C. STEUER FF. LAD. 110 MAR. 15, 1942 1943 CRIMMINS

FF Steuer was awarded the Crimmins Medal in 1943 for heroic duty performance rescuing 3 people at a fire March 15, 1942 at 43 Nevins Street, Brooklyn.

FRANCIS J. RYNIKER FF. LAD. 110 MAR. 15, 1942 1943 JOHNSTON

FF Ryniker was awarded the Johnson Medal in 1943 for heroic duty performance rescuing 3 people at a fire March 15, 1942 at 43 Nevins Street, Brooklyn.

FIRE BUILDING 43 NEVINS STREET

MEDAL DAY 1943

LADDER 110 MEDALS

JAMES J. C. STEUER FF. LAD. 110 MAR. 15, 1942 1943 CRIMMINS

FF Steuer was awarded the Crimmins Medal in 1943 for heroic duty performance rescuing 3 people at a fire March 15, 1942 at 43 Nevins Street, Brooklyn.

FRANCIS J. RYNIKER FF. LAD. 110 MAR. 15, 1942 1943 JOHNSTON

FF Ryniker was awarded the Johnson Medal in 1943 for heroic duty performance rescuing 3 people at a fire March 15, 1942 at 43 Nevins Street, Brooklyn.

FIRE BUILDING 43 NEVINS STREET

MEDAL DAY 1943

Last edited:

ENGINE 207/LADDER 110/SATELLITE 6/BATTALION 31/DIVISION 11 (CONTINUED)

ENGINE 207 MEDAL

JOHN L. CLARKE FF. ENG. 207 OCT. 20, 1952 1953 O'DWYER

FF Clarke was awarded the O'Dwyer Medal in 1953 for the off-duty daring rescue of a woman trapped on the 3rd floor at a fire on October 20, 1952 at 233 13th Street, Brooklyn.

FIRE BUILDING 233 13TH STREET

MEDAL DAY 1953

ENGINE 207 MEDAL

JOHN L. CLARKE FF. ENG. 207 OCT. 20, 1952 1953 O'DWYER

FF Clarke was awarded the O'Dwyer Medal in 1953 for the off-duty daring rescue of a woman trapped on the 3rd floor at a fire on October 20, 1952 at 233 13th Street, Brooklyn.

FIRE BUILDING 233 13TH STREET

MEDAL DAY 1953

Last edited: